Preface

For chip manufacturing, the most important piece of equipment is the photolithography machine. Previously, photolithography machines in our country were monopolized by foreign countries, and it was only in recent years that breakthroughs were achieved.

However, photoresist, which is also crucial for chip manufacturing, is predominantly produced in Japan, accounting for 90% of the global supply.

As a U.S. ally, what should our country do if Japan suddenly cuts off its supply?

Japan essentially has a monopoly on photoresist.

With the rapid development of China in the semiconductor field, the United States has also increased its blockade on our country's semiconductor sector.

Although the United States has leveraged its global hegemonic status to suppress Chinese semiconductor companies and has restricted Huawei from using advanced chips,

after several years of development and long-term strategic planning, China's semiconductor industry has still grown. Although there is still a certain gap compared to the world's leading process manufacturing levels, the overall progress is on track to catch up in a few years.

However, in the process of chip manufacturing, there is not only the photolithography machine. Although the photolithography machine is the most important core, there are many materials used to assist in chip design and production."Photoresist" plays a very important role in the field of chip manufacturing. It can be said that "photoresist" and high-end chips, especially chips for mobile devices, have a pivotal role in chip manufacturing.

However, currently, 90% of the world's photoresist is produced and manufactured by Japan.

Among the top five global photoresist producers, four are Japanese companies, and these Japanese companies account for more than 70% of the global photoresist market.

The output of photoresist produced by these companies has reached more than 90%, so in the field of photoresist, Japan can be said to be in a league of its own, with absolute say.

The reason why Japan has such great achievements in the field of photoresist and other semiconductor processing is due to the United States, which made Japan sign the "Plaza Accord".

Due to the signing of this agreement, Japan's foreign trade suffered a huge blow, so it had to rely on these emerging industries to maintain Japan's trade economy, so chip semiconductors became a key research direction for Japan.

At present, Japan, with a photoresist market close to 50 billion yuan, accounts for 70% of the global photoresist market.

It has also basically achieved a "monopoly position" in photoresist manufacturing.

So, since photoresist has such a large market, what role does it play in chip manufacturing?

The role of photoresistIn fact, at the beginning, photoresist was not used in semiconductor manufacturing technology, but was mainly used in photographic technology. Moreover, photoresist has a history of nearly 200 years, initially being used only in intaglio photography.

Since its inception, photoresist has never left the field of photo printing technology. However, in the 1990s, chip manufacturing gradually took shape, and photoresist found new applications. It was not until the advent of extreme ultraviolet (EUV) lithography that photoresist truly shone on the world stage.

We know that chip manufacturing is an extremely delicate task, generally requiring precision to the millimeter level, and more advanced chip processes can achieve details at the micron level.

Therefore, the difficulty of making high-end chips is also very high. However, the emergence of photoresist perfectly meets the manufacturing process of high-end chips. The main role of photoresist in chip manufacturing is to print patterns on the chip circuit board. With the physical properties of photoresist as an auxiliary, it can make the chip have higher performance.

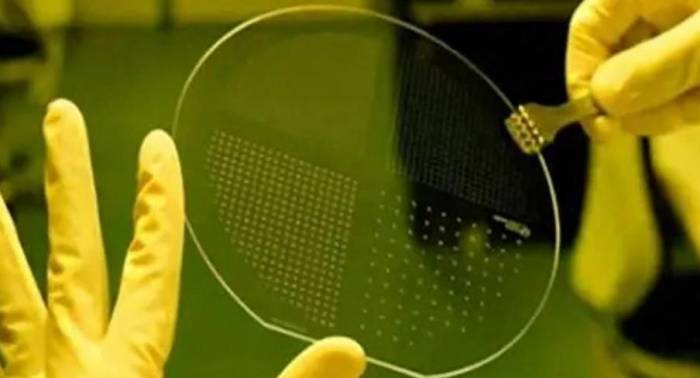

That is to say, the main function of photoresist is to define patterns for chips, and it also plays a role in protecting and isolating chips in chip manufacturing. Because the definition of patterns essentially determines the size, shape, and other details of the chip.Firstly, photoresist must be coated onto the surface of a silicon wafer. Then, using a photolithography machine, the circuit patterns from the chip design are transferred onto the photoresist through exposure to ultraviolet light. The exposure process fully transfers the pre-designed pattern shapes onto the chip to be manufactured. Therefore, the quality of the photoresist also determines the quality level of the chip. If the photoresist quality is very much up to standard and the technology is well applied, then the qualification rate of this chip will also be high. Currently, the most advanced process for photoresist has reached 7 nanometers, and it is an indispensable material in high-end chip manufacturing. It can be said that without the support of advanced photoresist, it is also difficult to produce high-end process chips. At present, Japan controls more than 90% of the global photoresist production capacity. As Japan is an ally of the United States, if it suddenly "strangles" us, how should we respond? How should our country respond?Undoubtedly, Japan's photolithography resin technology is highly advanced and controls the majority of the global production capacity. However, compared to Japan and some Western countries, China started relatively late in the development of photolithography resins, which puts it at a significant disadvantage. Nevertheless, this does not mean that China's photolithography resin technology is non-existent.

For comparison, China has even achieved new breakthroughs and development directions in photolithography machines, let alone the photolithography resin market. Although the start was late, with the efforts of domestic enterprises, domestic photolithography resins have also ushered in rapid development. After all, China has a photolithography resin market as large as 19 billion.

In particular, companies such as Nanjing University of Science and Technology (NUST) have invested heavily in research and development and manufacturing. After three years, they successfully developed China's first ArF photolithography resin, which is not inferior to foreign products in quality.

After the introduction of this fully self-developed ArF photolithography resin, it has received unanimous praise from the market, helping Chinese chip manufacturing enterprises in the development of chip manufacturing processes, and has been unanimously praised.

Moreover, the photolithography resins designed by Nanjing University of Science and Technology are at the same level as imported photolithography resins and can meet domestic demand. With the technological breakthroughs of Nanjing University of Science and Technology in photolithography resins, many domestic companies, including Suzhou Ruihong and Beijing Kehua, have achieved technological breakthroughs.

Moreover, the products produced by these companies have low metal impurities in photolithography resins, and their comprehensive performance has reached the requirements of high-precision chips, which can fully meet the current market demand.Therefore, the "photoresist" itself, although Japan still has a certain lead in the process, it is not comparable to the technology of photolithography machines. With effort and more research, it is possible to catch up with Japan.

For China today, it is sufficient to reach an average level in process technology. As long as it can be used normally, it can be used first.

We need to first fully establish the semiconductor industry chain. Only by establishing a complete domestic chip industry chain can the improvement of process technology not be far away.

This once again proves that China's scientific and technological development obviously has institutional advantages.

Conclusion

Therefore, it is very clear that in the field of "photolithography machines", Japan cannot "choke" and does not dare to choke.

After all, if I have what you have, and you don't let me use it, I can replace you in a minute.

This also proves once again that as long as we have enough strength, no one dares to choke us arbitrarily. Even if they choke us, we can exert the power of the system and continue to make breakthroughs!

Add Your Comment